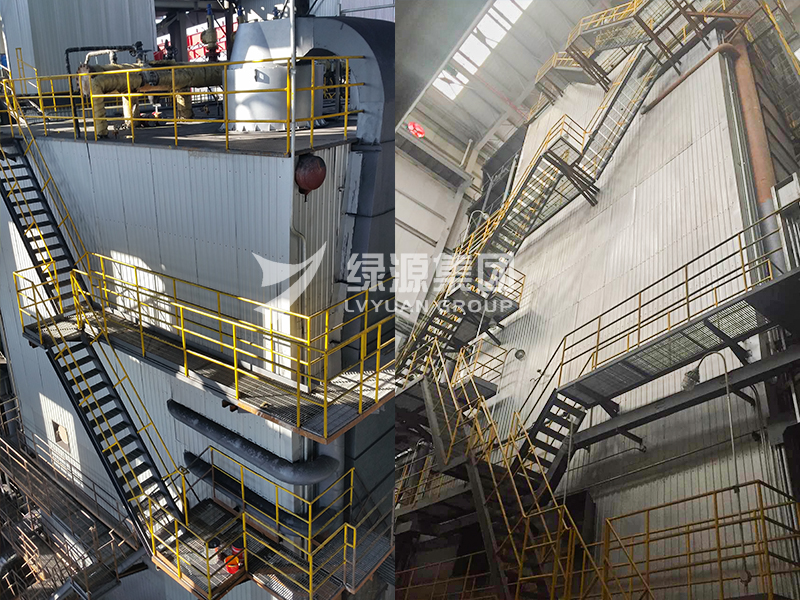

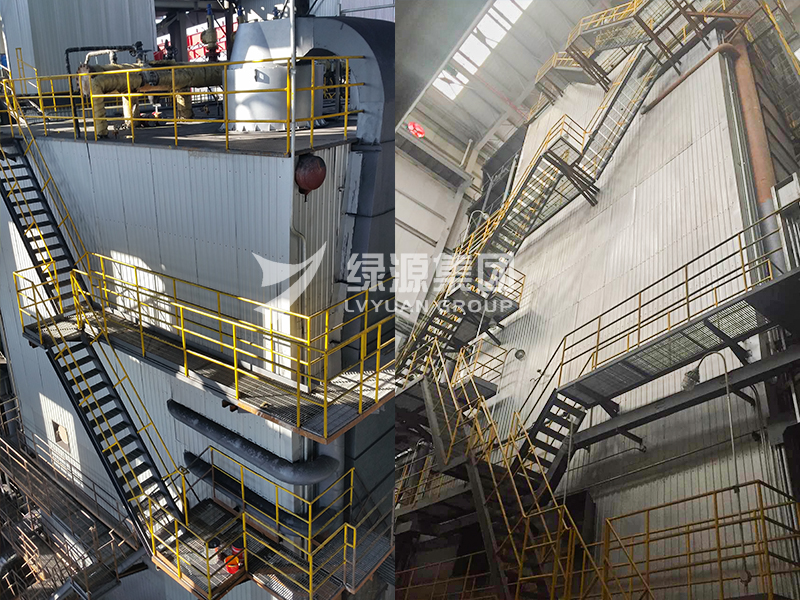

Pulverized coal boiler

Release time:2020-05-27 11:31viewed:times

● product information

Pulverized coal clean combustion technology is a national basic science and technology project, is an important way of coal clean utilization, is the national key promotion of energy conservation and environmental protection technology.

Pulverized coal clean gasification combustion boiler technology is to use high quality pulverized coal in the burner anoxic combustion to generate carbon monoxide (CO), CO in the case of anoxic combustion to generate carbon dioxide (CO2), so as to step by step complete the chemical conversion process of C+O2 exothermic CO2.This process is essentially different from the traditional pulverized coal boiler combustion process.

Pulverized coal clean gasification combustion system is the combination of combustion engine and combustion chamber, about 60% of the combustion process is completed in the burner, because the temperature in the combustion chamber is up to 1700℃, the combustion environment is lack of O2, so the release from the burner is mainly the mixture of CO and C, the probability of generating CO2 is small, the probability of NOx is smaller.

CO and C continue to burn in the absence of O2 in the furnace, eventually producing CO2.The supply of O2 in the furnace is completed in stages during the combustion process, which can effectively inhibit the formation of NOx.

Traditional chamber combustion boiler technology is a chemical reaction process in which C and O2 start to burn in the furnace, and finally complete C+O2 exothermal CO2. The defects of this process lie in the long combustion time, uneven distribution of O2, and the problems of low pulverized coal combustion efficiency and high NOx generation rate are easily caused.

Compared with the traditional technology, the combustion efficiency of pulverized coal clean gasification combustion system is higher and the environmental protection effect is more significant, especially in controlling NOx generation.

Product advantages

Compared with the traditional layer combustion boiler and fluidized bed boiler, the pulverized coal clean gasification combustion boiler system has prominent advantages, which are mainly manifested in six aspects:

I.High combustion efficiency

The process of pulverized coal clean gasification combustion is complex, including high-temperature precombustion, gasification combustion, and burning of carbon residue, etc., and the oxygen and carbon contact is full, the combustion condition is stable, resulting in the carbon combustion is very full.In the actual operation process, the residual carbon content of fly ash is between 0.5 and 3%, indicating that the combustion efficiency of the boiler is ≥99.5%.

II.Second, the environmental protection effect is outstanding

1. Clean coal gasification and combustion process is a mean of oxygen combustion process, the probability of a good contact with N2 and O2 is low, so the original NOX generate probability is very low, usually in the residual oxygen in flue gas < 6% of cases, NOX emission of the original concentration between 50 ~ 150 ㎎ / Nm3, after processing the SNCR technology, NOX concentration can drop to 80 ㎎ / Nm3, after processing the SCR technology, NOX concentration can be reduced to 30 ㎎ / Nm3.

2. Because of the way of clean coal gasification and combustion the combustion efficiency of 99.5% or higher, as a result, the pulverized coal fired boiler burn coal one-third less than conventional boiler, combined with the pulverized coal fired boiler with high calorific value and low sulfur coal as fuel, so the amount of total sulfur in coal consumption at least more than a third less than conventional boiler, so the total amount of SO2 in flue gas and dust than any other type of boiler is low.If the furnace is equipped with devices such as desulfurization by CaO method and cyclone dust removal, the emission of flue gas will be more environmentally friendly and can basically meet the requirements of ultra-net emission.

3. The combustion process adopts a completely closed type, that is, the fuel is closed, the combustion process is closed, and the ash and slag are closed. Therefore, dust pollution in the discharge process of traditional boiler ash and slag is avoided.

III. Strong adaptability of fuel

During the whole combustion process, carbon and oxygen will be fully mixed and burned at a low ambient temperature. This process has low requirements on coal types, so it is not necessary to select high-quality coal to ensure the combustion of the boiler.

IV. Obvious advantages in energy conservation

The boiler system adopts the design idea of gas-fired boiler in the design, the whole membrane water cooling wall closed structure, low heat dissipation loss, low smoke exhaust temperature, and high combustion efficiency, so that the thermal efficiency of the boiler is between 92~95%, at least 10~15% higher than other types of boilers.

V. unattended automatic walking

The idea of closed-loop control is adopted in the operation control of the boiler, and the operation state of the boiler can be automatically adjusted by the flue gas emission index, outdoor temperature, heating temperature, steam temperature and other indicators, without manual operation, and the unattended operation of the whole system can be realized.In the actual operation, boiler operators do not make major adjustments after setting operating conditions.

6. Good economy

1.The amount of fuel used by the boiler is small.Taking the hot water boiler as an example, under the condition of using high quality and low sulfur coal, the fuel cost in a heating period is estimated to be between 10 and 14 yuan/square meter.

2. The cost of environmental protection is low. Taking the hot water boiler as an example, the environmental protection cost of a heating period is less than 1 yuan/square meter if it meets the current national flue gas standard.

3. With sufficient combustion of fly ash and little carbon content, it can be directly filled into concrete for use, bringing obvious benefits.

● system introduction

Combustion technology

The combustion process is completed by the combination of mechanical combustion and chamber combustion under the condition of O2 deficiency.

Combustion process: pulverized coal is burned at high temperature in the combustion chamber of the burner under the condition of hypoxia. The whole process of drying, gasification, cracking and combustion is completed in a very short time and CO is generated. This process realizes the conversion of most solid fuels into gaseous fuels.

Chamber combustion process: CO and some C particles with high-temperature flue gas enter the main combustion chamber from the top of the boiler and complete the whole combustion process with the assistance of segmented wind.Incomplete combustion of CO and C completes the final combustion process in the burnout chamber.Combustion efficiency of pulverized coal can be improved by chamber combustion technology.99%.

The combustion equipment adopts zzr-lm series pulverized coal burner, which is a high-end numerical control burner designed and manufactured by integrating a number of combustion patent technologies. It is a stupid combustion machine with high intelligence, energy saving and environmental protection that can burn a variety of pulverized coal such as bituminous coal and lignite.

ZZR - LM pulverized coal burners combustion machine working principle and the traditional have essentially different, it is composed of high intelligence low nitrogen type pulverized coal burner and of the world's leading digital combustion control system, according to the coal supply in synchronous adjust the quantity of air blower, quantitative precision control for the number of pulverized coal and air, in the case of flame adjustment ratio of 5:1, ensure the calorific value in 4500-7000 calories, volatilization in 25-40%, pulverized coal fineness is 200 purpose can be in the best state of combustion, in the case of lower excess air coefficient can be still stable combustion fully burnt out.

Boiler technology

The structure of the boiler adopts the most advanced technology of Angle tube type full membrane water-wall boiler in the world, and the burner adopts roof type.The boiler is provided with a combustion chamber and an embers chamber, which take the form of multi-point segmented air supply.The convection tube bundle adopts serpentine tube convection heating surface, and SCR denitration space is reserved in the middle.In order to ensure that the temperature of denitrification is not affected and the low temperature corrosion of the convection heating surface is prevented under the condition of variable load, the boiler's backwater method adopts the patented technology of our company -- simulation method for subsection backwater technology.The hot water boiler has no barrel, and the water cycle is forced.The steam boiler is equipped with a drum and the water cycle is natural.The solid slag discharge can be realized by scientifically setting the furnace structure and controlling the combustion temperature.

Environmental protection technology

The core of environmental protection technology of pulverized coal clean combustion system is to ensure that low-sulfur coal can be burnt step by step under the condition of O2 deficiency at high temperature.In the first combustion process, due to the lack of O2, C can only react with O2 to produce CO. Because the activity of CO is stronger than that of N2, even if the partial oxygen enrichment is instantaneous, only CO2 can be generated, but NOx cannot be generated.In the second combustion process,

When CO reacts with O2, partial O2 supply is controlled by segmented multi-point air supply, thus inhibiting the chance of N2 and O2 reaction.

In order to reduce the production of SO2 and NOx, the system also adopts chemical environmental protection technology, that is, equipped with SCR and SNCR denitrification devices and desulfurization tower.

In order to control dust emission, the system is also equipped with high efficiency cloth bag filter.

Automatic control system

Automatic control system includes combustion control, boiler control, environmental protection control and other components, using PLC or DCS mode.The combustion part of the boiler is controlled and managed by the BMS system, which mainly collects data such as exhaust temperature, flue gas composition, fuel supply, temperature and pressure of each point in the furnace, etc., and realizes the control of the combustion process through automatic processing.The boiler system mainly controls the water entering and leaving process and safety of the boiler.Environmental protection control system is mainly through the boiler's various emission indicators to adjust the amount of chemical additives.

PREVIOUS:No Previous

NEXT:No NEXT

Sweep WeChat yards pay attention to us

Sweep WeChat yards pay attention to us